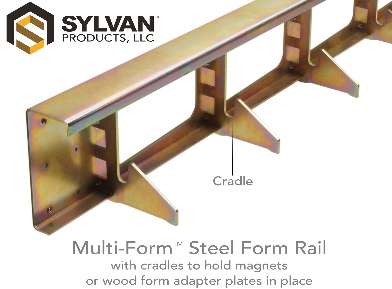

Made of durable galvanized steel, Multi-Form rails are part of an innovative precast forming system. They are designed to work with Mag-FlyTM Power Magnets on steel beds, and on adapter sets on wood beds, for fast, easy and exact forming. This advanced, German-engineered forming system from B.T. Innovation has been used across Europe for more than a decade, and now has caught on quickly throughout the U.S. for its ease, speed, precision and economical costs. Offered exclusively by Sylvan Products in the U.S.A.!

Mutli-Form rails are strong and stable to ensure perfect 90 degree angles and protection against twisting and bending. This system is regularly used to produce solid walls, sandwich walls, stem walls, landing slabs, balcony slabs, buttresses, beams, sills and more. The front of the forming support are mounted with face-plate or bulk-head material of your choice, whether it be Dura-Pour™ face strips, HDO or MDO strips, BBO & ES plywood, Combo-FormTM or custom steel or plastic faceplates. These faceplates are fastened from the back, such as with screws into the plywood, so the formwork remains undamaged—no screw indentations in the concrete. Eliminates time-consuming filing and sanding.

Feature:

- Saves time and materials—fast return on investment.

- Lightweight galvanized steel—easy to handle without a crane.

- Mag-Fly Power Magnets fit easily in place for fast, precise forming.

- Rails can easily be cut to construct custom block-out forms.

- Rail height can be increase by plywood or metal faceplates by a minimum of 4 inches above the rail height.

- Quick adjustments to change element casting dimensions.

- Simple handling—rails and magnets are not permanently connected together.

- The rails can be used in conjunction with other types and brands of precast formwork.

- Tailored sizes available to meet your customer’s requirements.