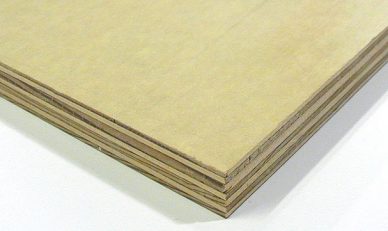

Sylvan’s high-end Armor-Ply™ Medium Density Overlay (MDO) Sign grade plywood is designed to meet the highest standards to meet applications for “paint-grade” applications, both for indoor and outdoor applications. This includes billboards, highway signs, office signs, soffits, siding, facia, cabinet liners, partitions, casework, modular furniture, and more. Armor-Ply™ MDO uses all pre-sanded Douglas fir substrate to provide for superior longevity, less grain and telegraphing during the life of the panel. The high integrity Armor-Ply™ construction features composed cross-bands for tight core gap tolerances for more than stringent APA specifications. These MDO Sign grade panels are highly resistant to weathering , delamination and also deliver the structural properties required for large sign installations.

Feature:

- Less tele-graphing & grain transfer over the life of the panel

- Superior longevity in painted applications

- “B” Grade Face and Back

- All Group 1, Structural 1 Species

- Available in lay-ups of 1 or 2-Side Overlay

- Tightly bonded Overlays provide high resistance to edge splitting and slivering

- Available in all standard sizes and thicknesses. 3/8”, 1/2″, 5/8”, 3/4″ – (all in 4×8’)

- Extra-long panels available by special order in 4×10 or 4×12

Panel surface-size options

| Feet |

4’x8’ |

4’x9’ |

4’x10’ |

4’x12’ |

2’x8’ |

2’x9’ |

2’x10’ |

2’x12’ |

| Millimeters |

1220x2440 |

1220x2745 |

1220x3050 |

1220x3660 |

610x2740 |

610x2745 |

610x3050 |

610x3660 |

Panel thickness options

| Inches |

1/2” |

5/8” |

3/4” |

1-1/8” |

| Millimeters |

12.5mm |

15.5mm |

19.0mm |

28.5mm |

| Ply |

5 |

5, 7 |

7 |

9, 11 |

Panel-longevity comparison (estimated)*

|

Standard MDO |

Armor-PlyTM MDO |

Armor-PlyTM HDO |

Dura-Pour™ Overlay Form Plywood** |

| Engineered systems |

25 |

45 |

80 |

185 |

| Gang forms |

15 |

22 |

45 |

85 |

| Job built |

10 |

14 |

25 |

35 |

Estimates based on vertical and structural use; longevity will be lower for horizontal and/or architectural applications.

*It is difficult to find exact data on the expected number of reuses from MDO, HDO and DURA-POUR™, as each jobsite, crew, mix design and operation conditions present different variables, maintenance protocols, or project specifications in terms of cutting; drilling, screwing or otherwise damaging panels. However, as a guideline, this chart gives an estimate of potential reuses of some overlay form panels, based on anecdotal experiences by different end-users in the industry. Proper care of the panels is essential. These figures do not guarantee future results, and will vary according to variables in usage, care, and maintenance. The figures on Dura-Pour only indicate potential structural re-use, but not for unblemished architectural finishes, for which the specifications by the architect will dictate whether the panels should be used for one or up to five pours.

** Dura-Pour figures are listed for structural use comparisons, when used for precast face-plates or some casting-bed applications. However, when Dura-Pour is specified for cast-in-place applications, it is generally intended for uses as an architectural form-liner for which the number of reuses is usually a lower concern and focus than the quality of the finish. Learn more about Dura-Pour.